Understanding Dosing Systems and Pumps: Ensuring Precision in Liquid Management

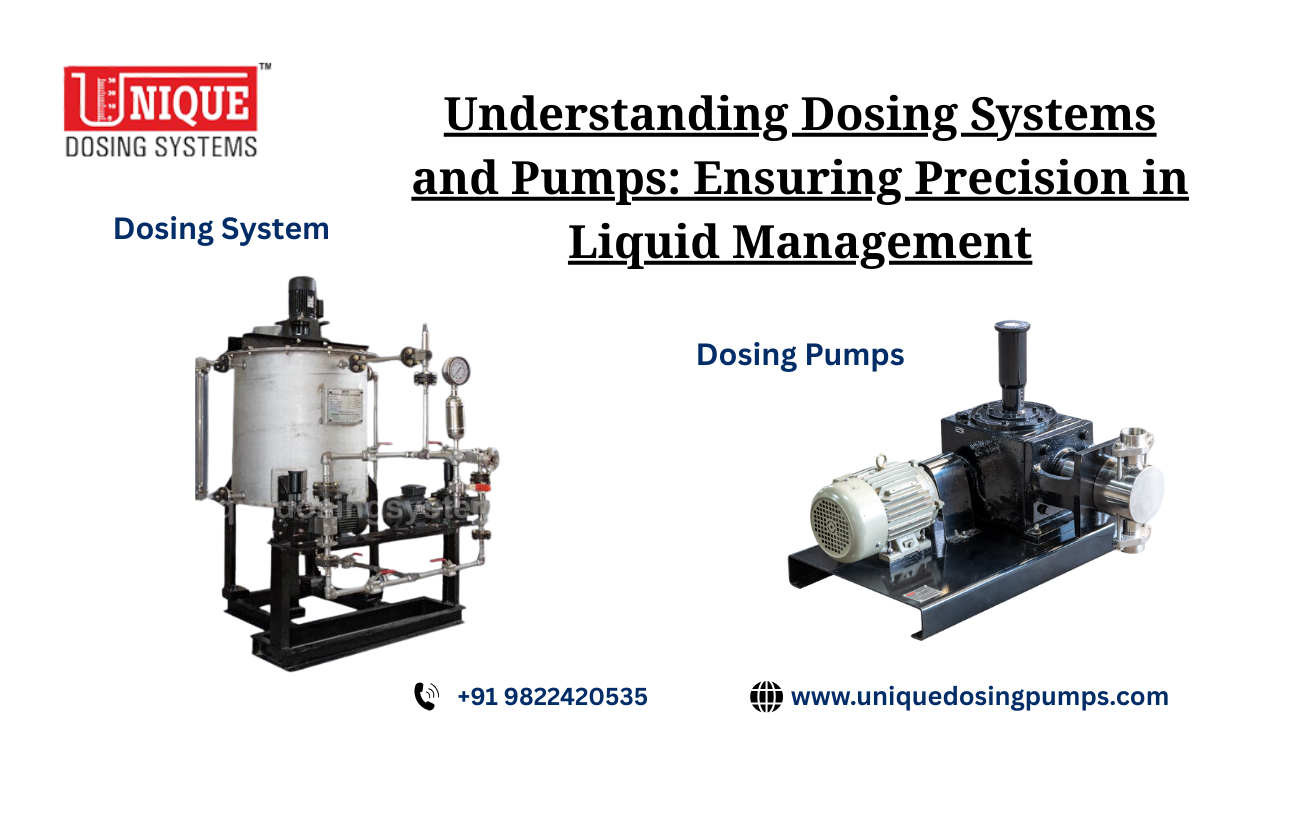

The effective management of liquids is paramount across a multitude of industries, from water treatment plants to chemical manufacturing. At the heart of these operations are dosing systems and dosing pumps, which ensure precise and accurate delivery of fluids necessary for complex processes.

What Are Dosing Systems?

Dosing systems are automated setups designed to deliver exact amounts of liquids into a process stream. They are essential for maintaining the correct proportions in chemical reactions, ensuring the effectiveness of water treatment operations, and even in the food and beverage industry for flavoring. These systems are highly valued for their precision, reliability, and the potential for cost savings by reducing waste.

The Role of Dosing Pumps

Central to any dosing system is the dosing pumps. These pumps are engineered to administer a predetermined volume of liquid with high precision. The pumps are typically categorized based on their mechanism of operation, including diaphragm, peristaltic, piston, and hydraulic dosing pumps. Each type has its specific applications, suited to different production environments due to its particular advantages and limitations.

Types of Dosing Pumps

- Diaphragm Dosing Pumps: These are the most commonly used type due to their versatility and precision. They work by varying the size of a chamber to move a liquid, ideal for chemical and water treatment purposes.

- Peristaltic Dosing Pumps: These pumps utilize a rotating mechanism that compresses a flexible tube, moving fluids through the dosing systems . They are notable for handling viscous liquids and slurries, making them useful in the food industry.

- Piston Dosing Pumps: Known for their accuracy, piston pumps operate via a piston that moves back and forth, providing a precise dosing capability. They are often used in laboratories for high-precision dosing tasks.

- Hydraulic Dosing Pumps: These use hydraulic fluid as a means of force, often incorporated into heavy-duty applications where high pressure and reliability are essential.

Applications of Dosing Systems and Pumps

The applications of dosing system and pumps are extensive. In the water treatment industry, these systems help in the steady addition of disinfectants like chlorine to purify water. In the agricultural sector, they are used for precise fertilizer application, ensuring optimal plant growth. In chemical processing, dosing systems maintain the integrity of reactions by ensuring that the right amounts of reactants are mixed.

In pharmaceuticals, the importance of dosing systems is underscored by their role in medication manufacturing and ensuring accurate dosages in mass production. Similarly, in the food and beverage industry, dosing systems guarantee consistency and flavor uniformity during production.

Conclusion

As industries continue to evolve and prioritize efficiency, dosing system and pumps will remain at the forefront of innovation. Their ability to ensure precision, reduce waste, and maintain consistency in liquid management processes makes them indispensable tools in the modern industrial landscape. Understanding the different types and applications of these systems allows businesses to optimize their operations and maintain high-quality standards.

Investing in the right dosing system can significantly enhance operational efficiency and product quality, solidifying its importance across various sectors.

Published on December 22, 2025 by Admin