Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

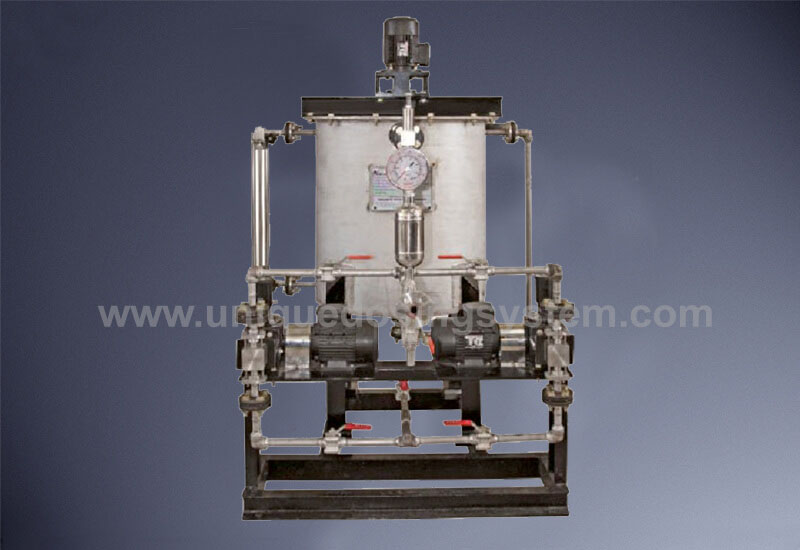

HP Dosing System HP Dosing System is generally accepted in the assiduity for dwindling scaling and maintaining the pH scale of liquid. The dosing entirely depends on pH scale variation of water present in barrel, therefore help the conformation of scale. Phosphate results are primarily used for the dosing purpose through this system. The system is manufactured using decoration grade of corridor that are sourced from dependable network of merchandisers. to check effectiveness of the system, it's tested on colorful quality parameters under the strict guidance of our professionals.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters