Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

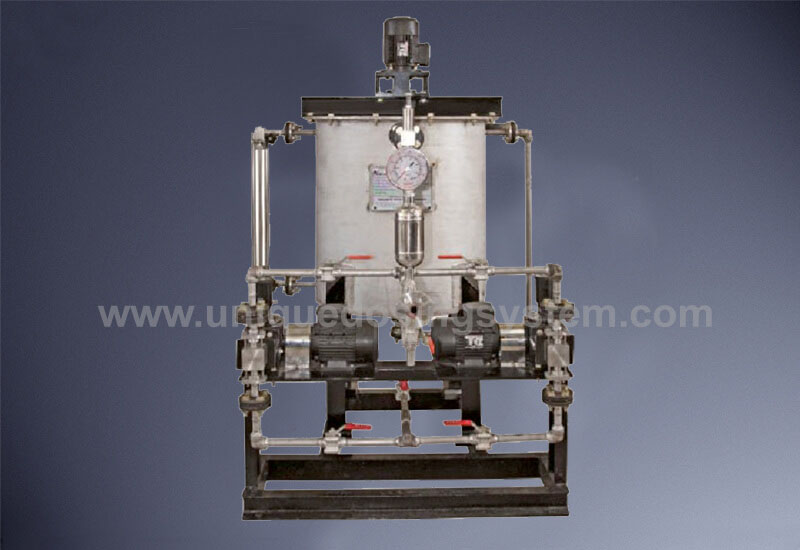

Bill Section LP/ HP Dosing System Fabricated following high end technology, Bill Section lp/ Hp Dosing System/ lp Dosing System is considerably conceded in colorful sugars and confederated diligence. The system comprised of different accessories as well as pressure relief stopcock, palpitation dampener, pressure hand, gate stopcock, flanges, pipes, fittings, position hand, ball stopcock, descent base plate and non return stopcock. The offered range is equipped with unmatched features like longer service life, effective performance, cost effective and high solidness.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters