Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

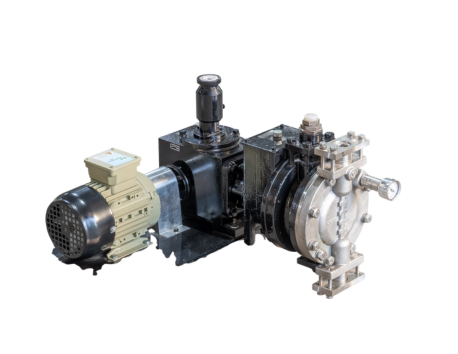

High Pressure Dosing Pump Unique Dosing Systems manufactures High Pressure Dosing Pump Manufacturers in customized form to meet the demand of our guests. High Pressure Dosing Pump is also known as low inflow and high pressure operation pump and performs colorful tasks in different diligence similar as food, chemical, pharmaceutical etc. This pump maintain inflow and delicacy and also able of dosing high pressure liquid to colorful situations. High Pressure Dosing Pumps are suitable for Chemical, Food and beverage, Paint, Petrochemical diligence and also in Dairy factory and Water treatment factory.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters