Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

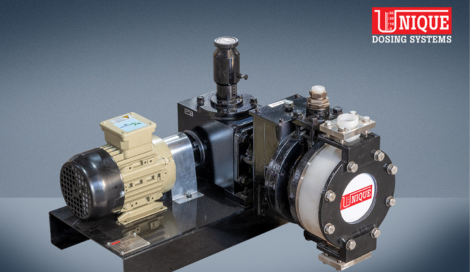

OurHydraulic Diaphragm Pump have superior in quality and well technically advance which requires minimum maintenance equipped with in built safety features such as pressure relief mechanism to avoid and accidents or unpredicted emergency. These pumps are economical in operation as well as capable of high pressure injection processing & servicing applications. These pumps literally offers trouble free operation over a long service life i.e. can be able to transfer various fluids including slurry, toxic chemicals & any fluid which get deteriorate when exposed to open air.

We design & Manufacture Diaphragm Pump with extreme precision facility available in our state of art unit at Mumbai based which have low running cost & easy to operate. Our technical team is consistently working to provide fatigue free product at customers’ door step. Strict quality control checks and utilization of high grade raw materials while manufacturing such high class product makes these pumps unique which distinguish our pumps from others in the same segment.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters

Hydraulic Diaphragm Pump We're leading & well established manufacturer of mightily designed Hydraulic Diaphragm Pump have colorful artificial operations. These pumps have extremely robust construction and leak evidence operation facilitates end stoner to transfer or dosing of multiple of aggressive chemicals at needed point. The separation chamber provides fresh safety in case of failure or crack of any confederated extra as no flooding of liquid from pump assembly or any other element. Hydraulic Diaphragm Pump OurHydraulic Diaphragm Pump have superior in quality and well technically advance which requires minimal conservation equipped with in erected safety features similar as pressure relief medium to avoid and accidents or unpredicted exigency. These pumps are provident in operation as well as able of high pressure injection processing & servicing operations. These pumps literally offers trouble free operation over a long service life i.e. can be suitable to transfer colorful fluids including slurry, poisonous chemicals & any fluid which get deteriorate when exposed to open air. We design & Manufacture Diaphragm Pump with extreme perfection installation available in our state of art unit at Mumbai grounded which have low running cost & easy to operate. Our specialized platoon is constantly working to give fatigue free product at guests ’ door step. Strict quality control checks and application of high grade raw accoutrements while manufacturing similar high class product makes these pumps unique which distinguish our pumps from others in the same member.