Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

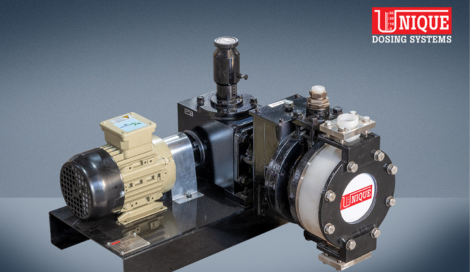

Hydraulic Actuated Diaphragm Type Pump These are designed for free inflow performance at advanced capacity & advanced pressure operations with extremely good suction lift conditions & slip evidence operation. A especially designed heavy duty Hydraulic Actuated Diaphragm Type Pump Manufacturers can handles sharp liquids similar as H2SO4, Ammonia, Hydrazine Solution and Sulphuric Acid including colorful chemicals with suction lift able to 16 bases also.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters

| Steady state accuracy | up to + 3 % |

| Accuracy at repeatability | + 3 % |

| Material for Construction | Stainless Steel, PVC, PP, FRP |

| Finishing | PU Painting |

| Brand | Unique |

| Automation Grade | Automatic |

| Condition | New |